Custom China PTFE Tubing

Offering Custom PTFE Tubing: Crystallization control ,Diverse Colors, Materials, Sizes, Lengths, and Specialized Features.

ISO 9001: 2015 Certificated Factory

13000 Sqm Industry Zone

Export ptfe tubing for 10 years

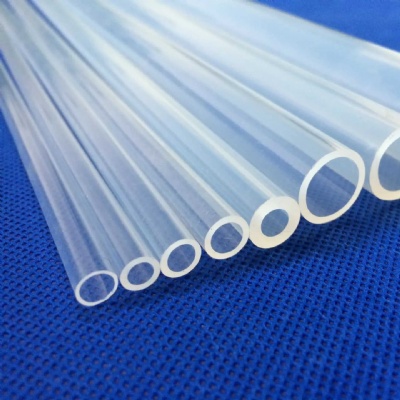

1. AWG Size: Available for various electrical applications,ptfe spaghetti tubing AWG1-AWG30

2. Standard Sizes: Widely recognized dimensions for industrial use,ptfe standard tubing covers ID2mm~ID30mm

3. Wall Thickness: Options to fit application-specific needs, 0.2mm to 4mm wall

4. ID and OD Variations: Custom inner and outer diameters ensure a perfect fit for any system,like thin wall ptfe tubing, heavy wall ptfe tubing.

5. Polytetrafluoroethylene tubing Metric size and imperial size ptfe tubing available.

PTFE Tube color customzation:

One of the standout features of custom ptfe tubing is the ability to select colors tailored to your application or branding. Here are the available options:

One of the standout features of custom ptfe tubing is the ability to select colors tailored to your application or branding. Here are the available options:

<1> Milky PTFE extruded tubing: Ideal for applications prioritizing durability and chemical resistance over clarity.

<2> Translucent PTFE Tube Colors: Allows users to monitor media flow while maintaining chemical resistance.

<3> Colorful ptfe tubing: Custom colors enhance visibility and safety in various environments.such black, green,orange,brown,etc.

<4> Transparent FEP Tubing: Provides high clarity for visibility and resistance to harsh chemicals.

<5> Transparent pfa teflon tubing: High purity modified ptfe, withstand high temperature, chemical-resistant.

<6> PTFE Strip Tubing: Available in various colors and thicknesses, suitable for specific functional needs.

Why Choose our PTFE Tubing over other Chinese manufacturers ?

1. Trusted by customers like LG Display, Dongfeng-Nissan, Samsung Electronics.

2. Crystallization control of ptfe tubing improves heat, lifespan, and acid resistance. Check Details

3. Manufactured using PFOA-free PTFE resin.

4. Eight years' manufacturing experience with a 10000 M2 self-owned industrial zone.

5. Also manufacture FEP tubing stainless braided PTFE Hose.

Milky White PTFE Tubing

Milky color PTFE tubing is a variant of PTFE tubes that has a milky-white appearance due to its semi-translucent material properties. It maintains the performance characteristics of PTFE, offering high chemical resistance, excellent temperature tolerance, and non-stick properties.

Semi-transparent PTFE Tubing

It is semi-clear PTFE tubing which withstands extreme temperatures and resits a vast array of chemicals.

AWG size PTFE Tubing

PTFE AWG(American Wire Gauge) tubing is specially designed for electrical insulations applications which require high-temperature resisstance as well as chemical and abrasion resistance.

Transparent PTFE FEP Tubing

Just like PTFE, FEP tubing is another type of fluoropolymer tubing known for its chemical resistance and low friction. However, FEP tubing,weldable, is clearer and more transparent than PTFE tubing. Despite this, it can only withstand temperatures up to 200°C, while PTFE has a higher limit of 260°C.

PTFE multi-layer tubing

PTFE Multi-layer tubing is with a PTFE/FEP inside and PE/Nylon/PVC/PU outside. It offers chemical and friction resistance, moisture and temperature telerance.

PTFE(Polytetrafluoroethylene) tubing is a type of tubing know for its high chemical resistance and temperature durability, making it well-suited to a variety of applications:

1. Wide Operating Temperatures: PTFE offers wide operating temperatures from -400° F to 500° F.

2. Resistant to Corrosion: PTFE is highly resistant to corrosion, making it an ideal substitute for materials which show susceptibility to corrosion, like certain rubbers.

3. Superior Electrical Properties: It exhibits excellent electrical properties, including high insulation resistance and low electrical losses. These characteristics make PTFE tubing ideal for several applications in the electrical and electronics industries.

4. Unlimited Shelf Life: PTFE is highly stable, offering unlimited shelf life.

5. High Resistance to Water, Moisture & UV: It also shows high resistance to water, moisture, and UV light.

6. Low Coefficient of Friction: PTFE tubing is characterized by a low coefficient of friction. This property makes it useful in applications where sliding action of parts is needed (e.g., gears, slide plates, bushings, etc.).

7. High Flexural Strength: In terms of mechanical properties, PTFE tubing has high flexural strength, allowing it to maintain its integrity under stress.

8. Excellent Chemical Resistance**: PTFE is resistant to most chemicals and solvents. Its chemical inertness makes it suitable to use in environments where many other materials would degrade.

9. Non-stick Attributes: PTFE is widely known for its non-stick properties which is why it is popularly used in kitchenware and in applications where materials should slide freely.